Of future experiences. Clients to impress. Miles to run. Dance floors to master. Mountains to climb.

You pay for a new pair. At home, you open the shoebox. New shoes always smell of expectations.

You know what? If they’re made of leather, then they share a very similar story with other leather shoes.

And there’s another thing here too. The visible footprints that your shoes left somewhere far away.

Our shoes – yours and mine – are made in home workshops or factories. What kind of material do the manufacturers use? Often it’s an animal skin that needs further processing. That’s the purpose of the leather industry.

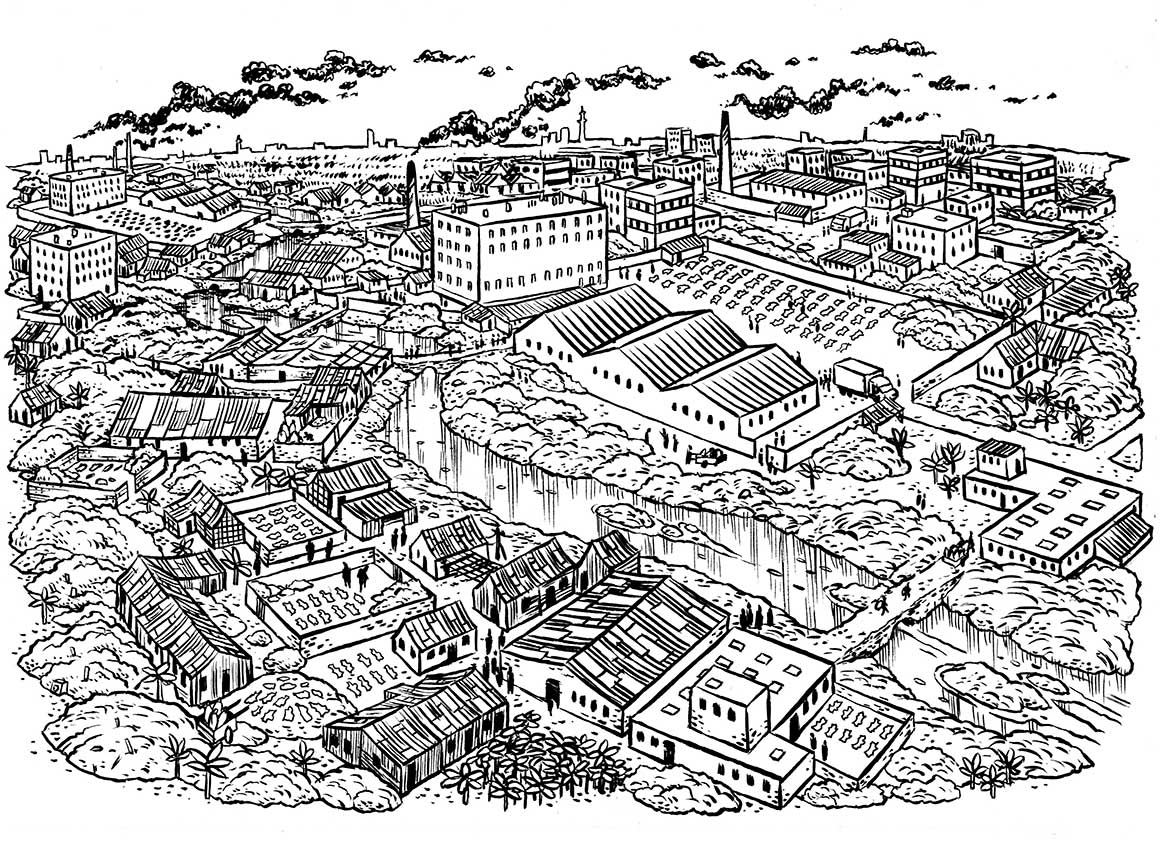

How does it all look at the very beginning, in the places where leather shoes are born? Join us on a little walk around Dhaka and find out.

Walk around Dhaka?

Dhaka is the capital city of Bangladesh, a country in Southeast Asia with 14.5 million inhabitants as of 2016. Bangladesh relies very strongly on the fashion industry. And Dhaka is an important hub for the leather and footwear sector.

In 2016, Bangladesh exported 48 million pairs of shoes. 42% of these were leather shoes. Millions of pairs are sold right in Bangladesh. The Bata Shoe Company is the second most important actor in the Bangladeshi footwear industry.

Not all shoes begin their journey in Bangladesh. And not all of them are leather shoes.

- Footwear production

- Footwear consumption

- ØAverage export price (per pair)

Source: The World Footwear Yearbook, 2016 and 2017

Ø 16 USD

North Amerika

15 %- United States 10.8 %

- Mexico 1.1 % 1.5 %

Ø 8 USD

South Amerika

7 %- Brazil 4.1 % 4 %

- Argentina 0.5 %

Ø 23 USD

Europe

16 %- UK 2.5 %

- Germany 2.1 %

- France 1.9 %

- Italy 0.8 %

- Spain 0.4 %

Ø 10 USD

Africa

7 %- South Africa 0.3 %

- Egypt 0.3 %

Ø 17 USD

Australia

1 %Ø 7 USD

Asia

54 %- China 57 % 18.3 %

- India 9.8 % 10.6 %

- Vietnam 5.2 % 1.1 %

- Indonesia 4.8 % 4.1 %

- Pakistan 1.6 % 1.8 %

- Bangladesh 1.7 % 1.8 %

- Japan 2.9 %

% share of the total volume (by material)

Export

- Leather

- Rubber/Plastic

- Textile

- Water-resistant/Other

Value

Did you know that...

– 75% of the world’s footwear is sent towards just 20 countries?

– in 2016, the largest footwear producers in Europe were Italy (188 million pairs of shoes), Spain (100 million pairs of shoes) and Portugal (82 million pairs of shoes)?

– in 2016, 23 billion pairs of shoes were made worldwide?

What are the worst consequences of shoe manufacturing? Loosen your shoes’ tongues and let them tell you.

The production of a single shoe usually includes a large number of different processes. For example, this sneaker (a Gel Kayano by Asics) may consist of as many as 26 different materials and 65 individual components. In total, this means 360 production steps.

The worker at the beginning of the production chain is not at all the one who profits from shoe production the most.

Drag the correct amount to each step in the supply chain – figure out how much it contributes to the retail price of shoes.

World Shoes

VAT 20 €

Total to pay 120 €

Wages are equivalent to 2% of the retail price. Approximately a quarter of the price goes to the brand, and a third to the retailer.

The analysis of the cost breakdown for trainers made in Indonesia proves that brands and retailers take advantage of high margins. Certainly, workers are not given their fair share of the profits.

How can we change that?

Every one of us should take a step forward.

Companies, together with political leaders, bear responsibility for the conditions in the footwear sector. Companies should:

- guarantee fair wages and decent working conditions for workers in shoe manufacturing;

- openly inform of how and where their shoes are produced;

- meet their responsibilities, account for negative impacts, and compensate the potential victims of their production activities instead of blaming local governments.

Governments and political leaders must guarantee a legal framework for safe and decent working conditions and for their enforceability. At the same time, they should set a wage level that can secure a decent standard of living for workers and their families.

As consumers, we have the right to be sold safe products and to receive information about production conditions. We have the right to know the conditions in tanneries and factories. We need to be sure that shoe-industry workers are paid at least a living wage. At the moment, it is almost impossible to find out where a particular pair of shoes was made and under what conditions. Therefore, customers should demand transparency and accountability from companies. Only then we will be able to hold brands and manufacturers accountable.

What do you think?

Can you now see the footprints you leave behind?

Tell us and tell your friends!

Promote this website on social media and add a short comment about your new shopping habits.